Once you’ve settled on a business

High-end decorative color film, anti-fingerprint film.Gold (Titanium Nitride, Zirconium Nitride, Titanium Nitrocarbide), Black (Titanium Carbide, Chromium Carbonate, Tungsten Carbonate, Diamond-like), Silver, Blue, Coffee and Miscellaneous, etc.

The process is easy to adjust, has strong repeatability, uniform and delicate film layer, good brightness of the film, is not easy to scratch, wear-resistant, and will not change color for a long time.Low energy consumption, high cost performance, small footprint, rich color range, easy operation and maintenance.

Vacuum chamber size: customizable to customer requirements Fully automatic electronic control system: touch screen smart interface

Nickel foam (hybrid car battery material), metal coating, conductive film

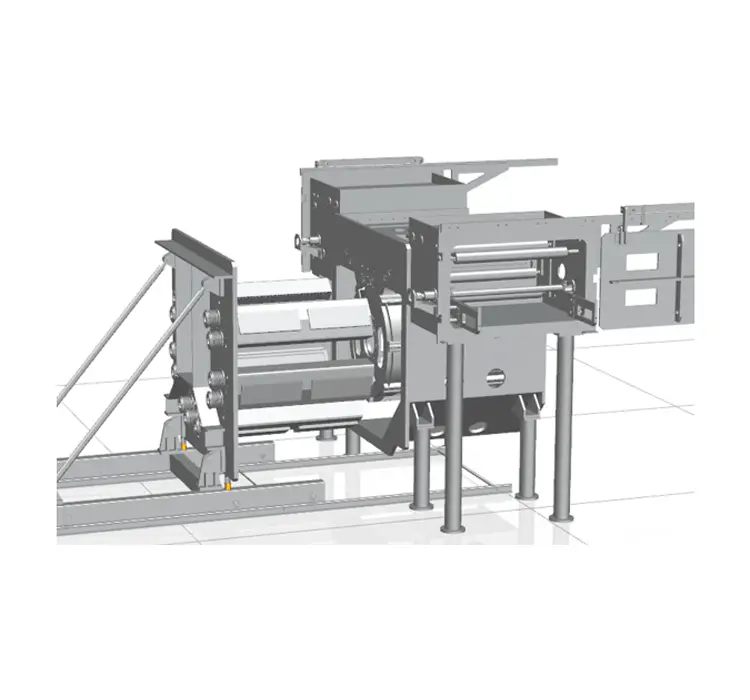

Six planar sputtering positions, double-sided coating, reciprocating continuous concept, flexible multi-layer system, compatibility with multiple flexible materials, automatic coating process

Typical base material types: PE, foam

Base roll diameterφ1050mm

Coiling speed 5 m/min

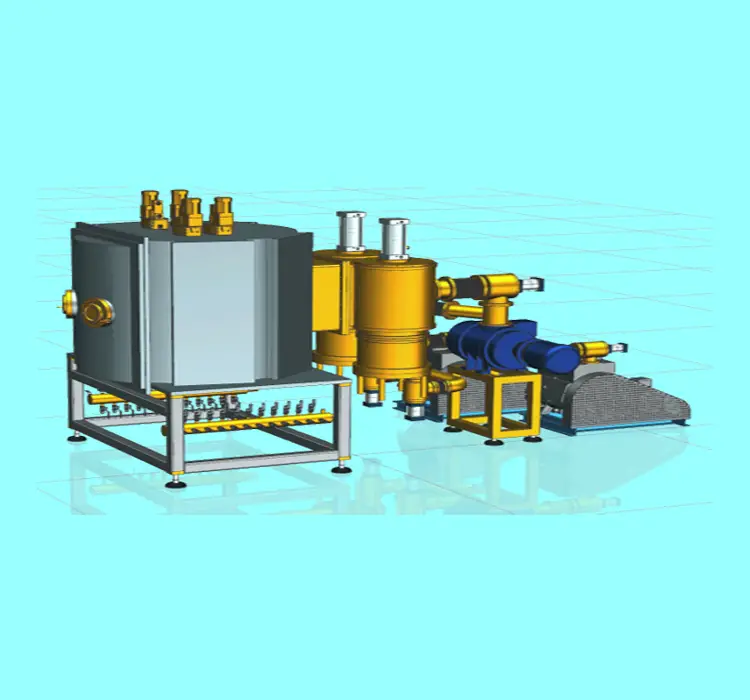

Printing Packaging Film, Gold and Silver Wire, Paper, Capacitive Film, Flexible Circuit Board

12 sputtering targets for multi-layer coating of multiple materials at once Compatible with a variety of flexible materials

Typical base material type:PET、PI、CPP、BOPP、PCV

Roll diameter of base material can reach 700mm

Coating method: single side

The thickness of the base material PET&PI can be as thin as 12μm

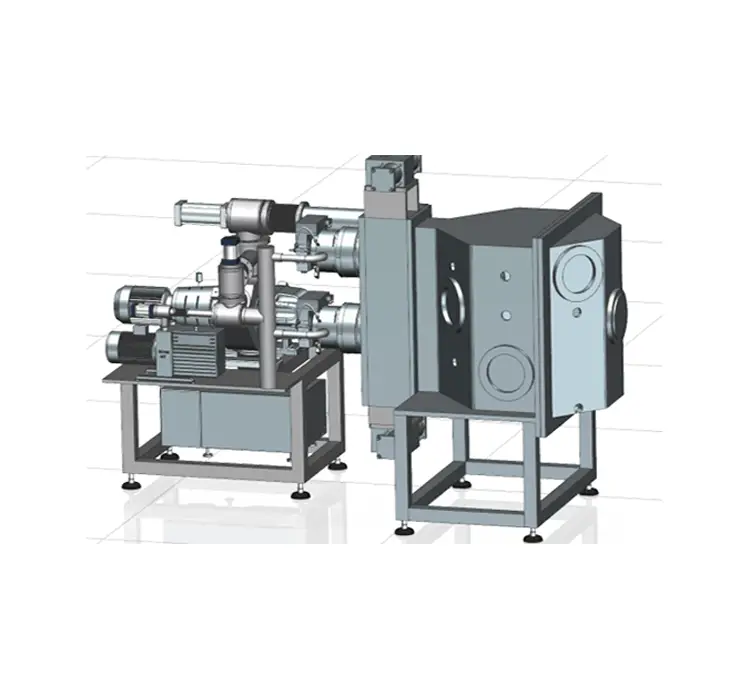

Optical and electronic thin films such as TFT, LCD, solar energy, etc.It can be plated with oxides such as ITO, AZO, Nb2O5, SiO 2, Al2O3, Ti, ZrO, nitrides such as AlN, SiN, ZrN, TiN, and pure metal films such as SiAl alloy, Mo, Cr, Ti, Zr, etc.

Modular design, high-end configuration of imported components, automatic return of substrates, automatic control system using PC+PLC, cathode selection (flat or rotating cathode)

Substrate size: up to 2200×2500

Metro: 35'a beat at the fastest speed

Coating method: single-sided and double-sided

Customization

Decorative and optical membranes for mobile phone structures

12-hole large crucible for multi-layer coating

High-precision control of high-speed workpiece rotation

Real-time monitoring of optical film thickness

Maximum Inside Diameter of Equipmentφ2700mm

Coating method: single-sided

DLC coating with anti-wear and lubrication coating deposited on the surface of parts such as moulds, knives or automobiles, sewing machines

The surface hardness of the coated product can be greatly improved to over 2500HV, and it has a very low friction coefficient (less then 0.1). It can significantly reduce the scratches and friction produced during processing, and greatly improve product quality. Four planar targets and two ion sources: planar targets and number of ion sources can be configured on demand

Vacuum chamber volume:φ1000*1000

Task: 18, or on demand

The series uses dynamic dual-drive magnetically controlled cathode arc technology with high ionization rate.TiN, CrN, TiAlN, AlTiN, AlCrN, AlCrSiN and other single or multi-layer systems can be prepared.Efficient pre-coating ion etching technology ensures the binding force and performance of the coating.This series of devices do not need to lay a bottom layer (transition layer) during the coating process, and directly form a film with high deposition efficiency.

Cathode arc:φ160mm Dual-drive Dynamic Magnetically Controlled Cathode Arc×6 Planar Rectangular Gas Ion Source

Vacuum chamber volume:φ1250*1100

Task: 10, or on demand